COMPLETE TURNKEY RESPONSIBILITY

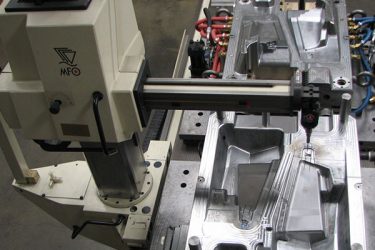

At Basic Tool, we design, build, repair medium to large molds for various industries that include automotive, alternative energy sources, appliances, housewares and furniture.

Basic tool utilizes only modern computerized equipment in both engineering and manufacturing. We are continually upgrading our technological capabilities. With a work envelope that is 200″ x 100″ x 80″, our manufacturing processes include 3 and 5 axis High Speed Milling, CNC Contouring, EDM, Turning, Metrology, and more. We build tools from 200 to 3,000 tons.

CNC Capabilites

28 CNC machines to handle blocks as large as 118×90 to small detail inserts. 4 machines are full 5 axis finishing machines with speeds up to 30,000rpm.

6 CNC machines for 3 axis high speed finishing. 2 Boring mills feature multi axis capability.

Programming is achieved with 4 seats of powermill ultimate and standard.

All machines feature FCS work holding capability, which Basic Tool has been implementing since 2017.

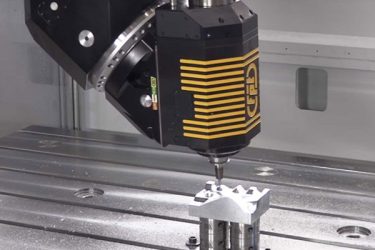

5 axis High Speed Finishing

Breton Matrix 800 – 1600 x 2000 x 800 – 20,000rpm

Parpas Omnia 32 – 3000 x 2500 x 1500

Fagima

Hurco VMX42CRTi **New** – 1100 x 600 x 600 – 12,000rpm

3 axis High Speed Finishing

Eumach

Rambaudi Ramspeed

(4) Fagima

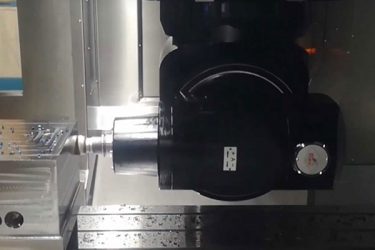

Boring Mill

FPT Full 5 axis **New**

Novar 4 axis Rotary Table

Novar 3 axis

Novar 3 axis

Bolla

3 axis CNC Milling Machines

Sachman

V-Tech

Rambaudi

Matsura

Okuma

Eumach

China machine **New**

Hurco VMX 42

Hurco VMX 30

Hurco VMX 30s

Hurco VMX 24

Hurco VMX 24s

Hurco

EDM

(3) Ero-Tech

(2) Euro-Tech

Lathe

Milltronics CNC

Standard lathe

Sawing

Table saw

Bar feeder saw

Grinding

Large #1

Large #2

Pedestal grinders

Material Handling

(2) Fork Lift

Blue Giant

Spotting

Software

Mold Design:

Vero Visi 3D – 3 seats

Formats Supported: Unigraphics, Catia, parasolid xt, step, iges, JT

CNC Powermill Ulitimate – 2 seats

CNC Powermill Standard – 2 seats